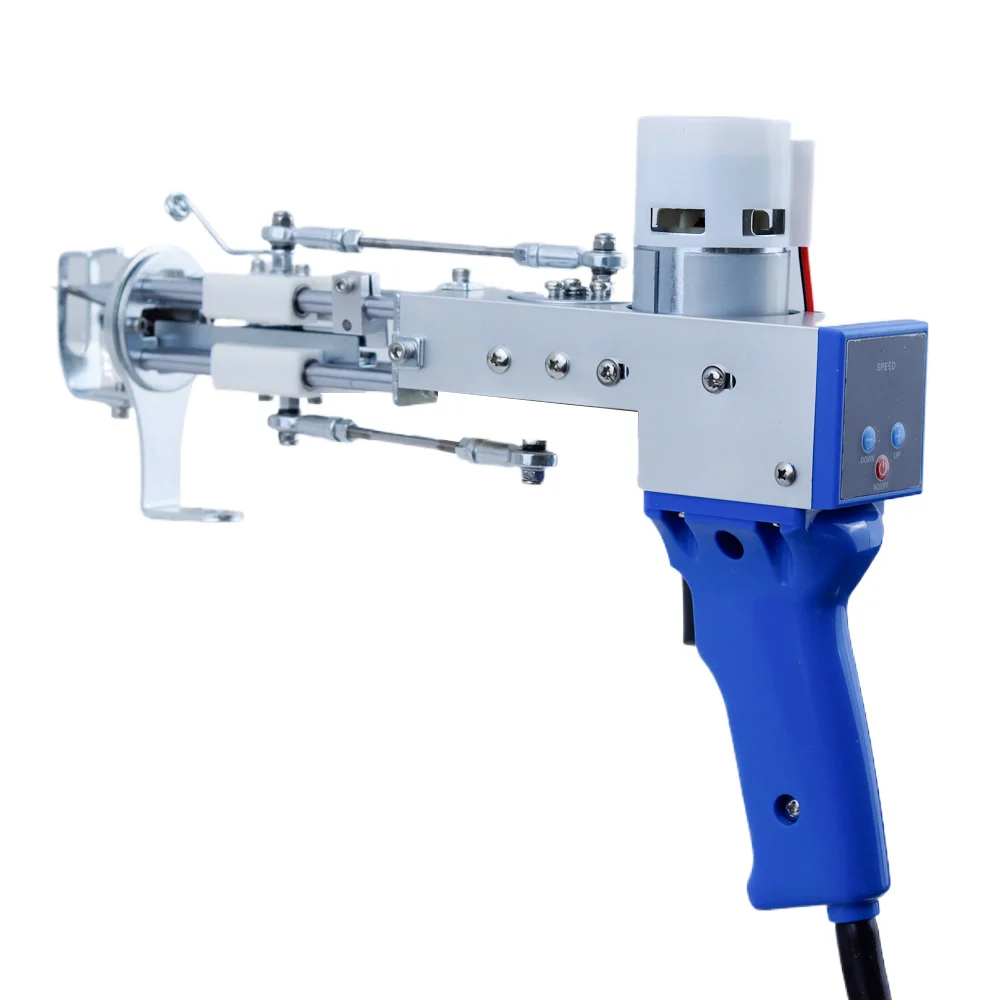

The new intelligent control tuft gun carpet weaving flocking machines are an upgraded version of traditional tufting tools used for making rugs. These machines feature advanced technology for precise and efficient tufting. The smart control system allows for easy operation and customization of patterns. The tuft gun tool is designed to enhance the quality and speed of carpet weaving. With its improved features, this machine is ideal for professional rug makers and textile manufacturers looking to increase productivity and create high-quality products.

Verbesserte Version Intelligente Steuerung Tuft Gun Teppichweberei Beflockungsmaschinen Tufting Rug Gun Tool

1、 Betriebsprozess

After the machine is powered on, the screen will display for 2 seconds before entering standby mode. Click the power on button to enter the working mode. The current set speed will default to 5 gears and display "05". Zu diesem Zeitpunkt, press the start button to start the machine. Release the start button to stop working. Before stopping, the actual motor must be detected to stop the Hall position. The Hall signal is a fixed-point shutdown function.

2、 Schutzmechanismus

Hall protection, if no Hall signal is detected within 3 seconds after the motor is started, it is considered a Hall fault or motor blockage: E2 is displayed, and it needs to be powered off again to recover.

Resolve issues after upgrading

1. The gear shift is clearly visible, und die 1-10 gear button is used for shifting. Compared to the old rotary knob for digital transmission, it can more clearly and intuitively know what speed you need.

2. Intelligent brake reset, using intelligent control chips to control the braking radius of each speed range. Compared to the previous magnetic induction electronic brake, which caused inaccurate sensing signals and brake reset deviation, intelligent control brake can accurately control the brake reset without deviation.

3. Increase motor stalling protection. In case of yarn entanglement or inadequate maintenance causing the weaving gun to not run after startup, E1 will be displayed and the weaving gun will enter the protection state. It is necessary to power off and clean the yarn or maintain the linear slider before restarting.

4. Hall protection: If no Hall signal is detected within 3 seconds after the motor starts, it is considered a Hall fault and displays E2. It needs to be powered off again to recover.

Rezensionen

Es gibt noch keine Rezensionen.