2024 NEU 4 IN 1 Raycus 1500W Faser -Laserschweißreinigung Schneidmaschinenschweißnahme sauberer Maschinenwasserkühler

|

Modell |

Faserlaserschweißmaschine |

|

Laserwellenlänge |

1070nm |

|

Laserkraft |

1500W |

|

Betriebsart |

Kontinuierlich/Puls |

|

Länge der Glasfaser-optischen |

10M(Standard) |

|

Schnittstelle von Glasfaser-optisch |

QBH |

|

Modulleben |

100000HRS |

|

Stromversorgung |

220V / 380V |

|

Kühlmethode |

Wasserkühlung |

|

Laserenergiestabilität |

<2% |

|

Luftfeuchtigkeit |

10-90% |

|

Empfohlene Schweißdicke |

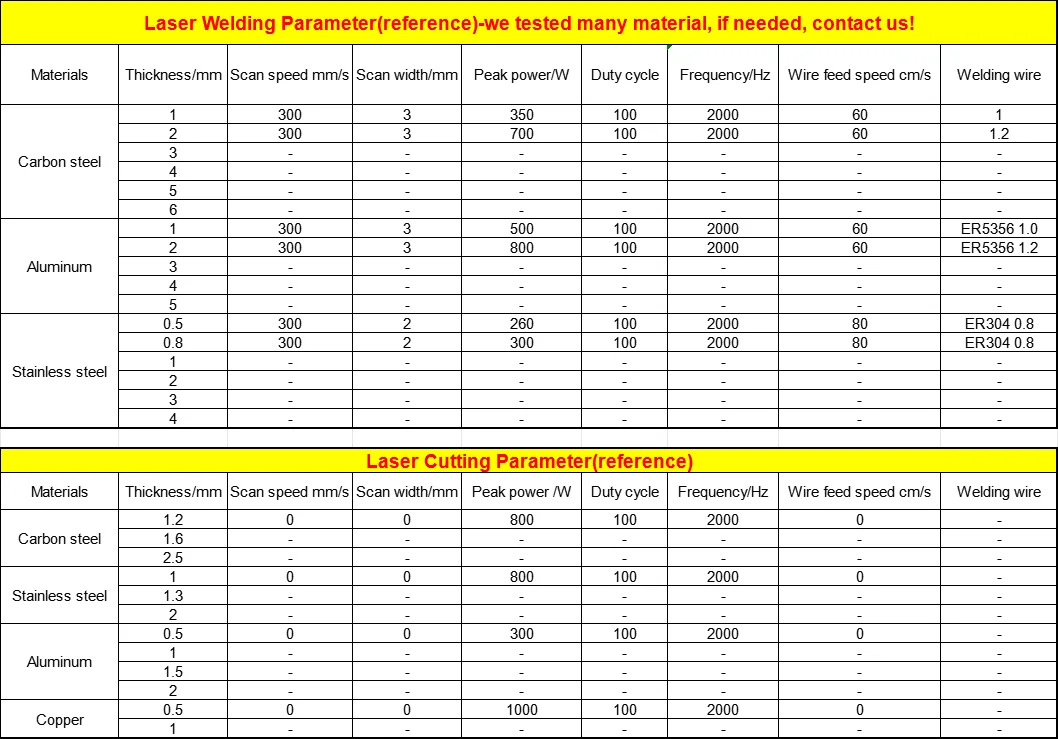

1500W Edelstahl, Kohlenstoffstahl 0-2mm |

|

Rotlichtpositionierung |

Unterstützung |

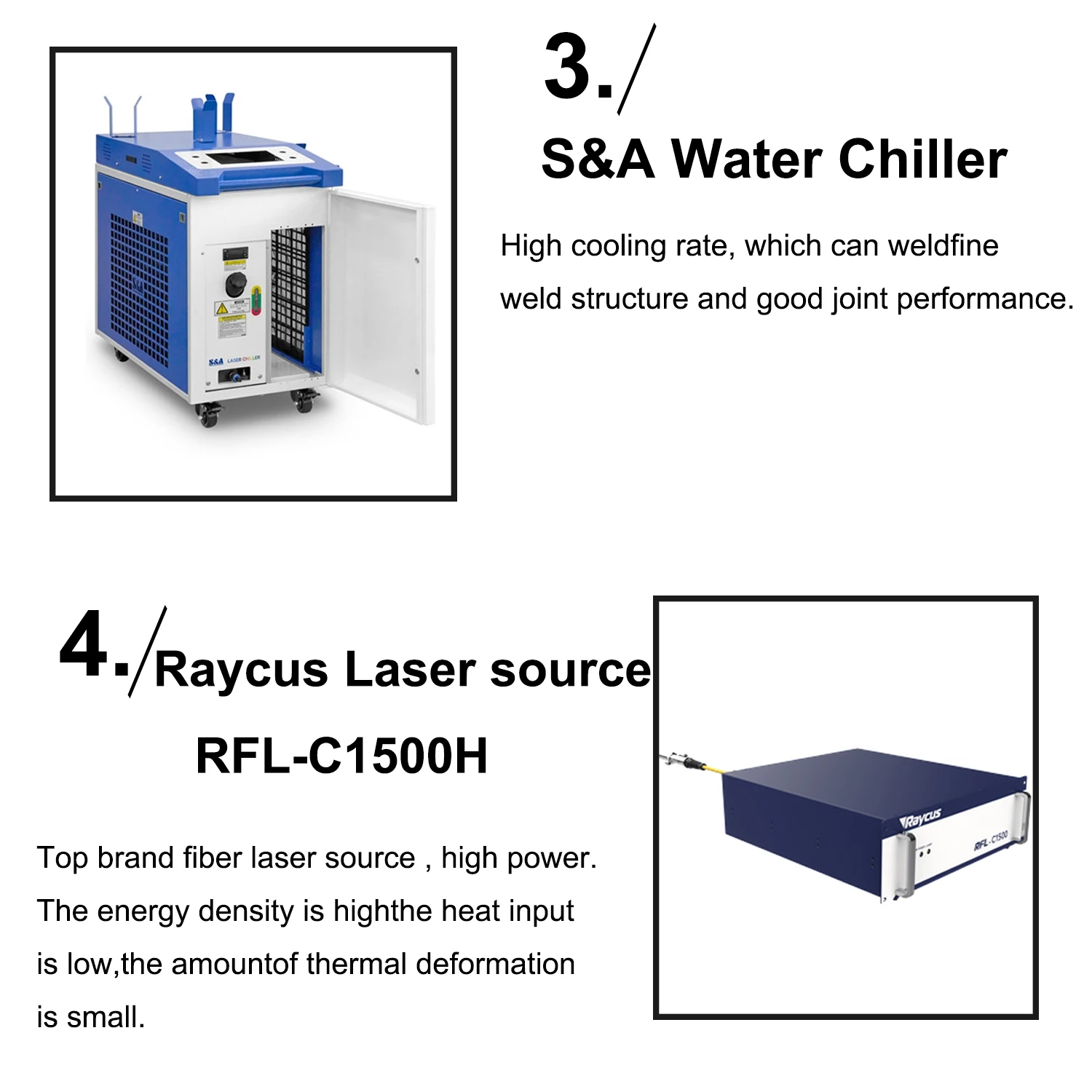

Seine Handheld -Laserpistole können Metalle schneiden und schweißen und Rost reinigen, malen, Harz, Beschichtungen, Öl, und Flecken.

Als Laserreiniger, it is a "green" Reinigungsmethode. Es muss keine chemische Wirkstoff- und Reinigungslösung verwenden. Der gereinigte Abfall ist im Grunde festes Pulver. Es ist klein, leicht zu speichern und recycelbar. Es kann leicht das Problem der Umweltverschmutzung lösen, die durch chemische Reinigung verursacht wird.

Als Laserschweißer, Die Schweißnaht ist glatt und schön, Keine Notwendigkeit zu polieren, Keine Verformung oder Schweißnarbe, festes Schweißen des Teils. Zeit sparen und die Effizienz verbessern.

Als Laserschneider, Es ist sehr einfach zu bedienen, alle Arten von Metallen zu schneiden.

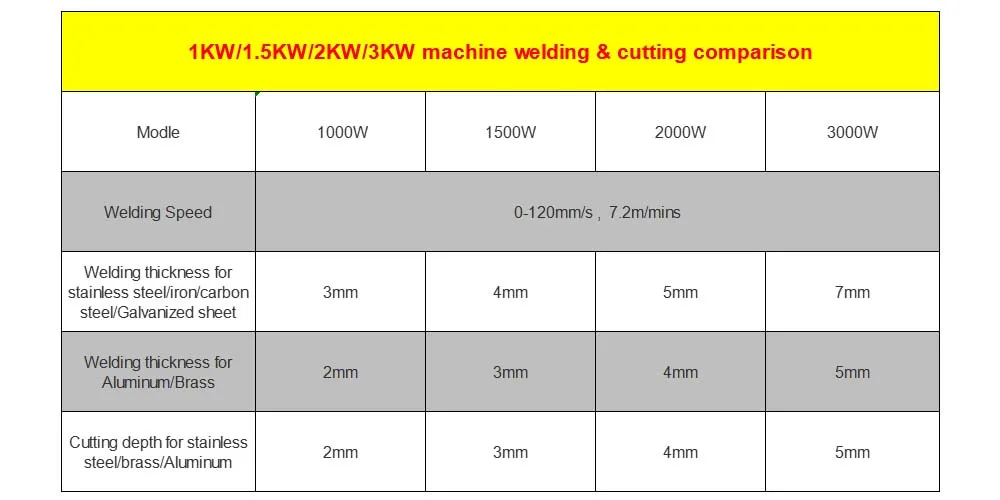

● Ralcus Laser

Im Vergleich zu traditionellen Lasern, 100000+HRS -Faserlaser sind stabiler, energiesparend, und wartungsfrei.

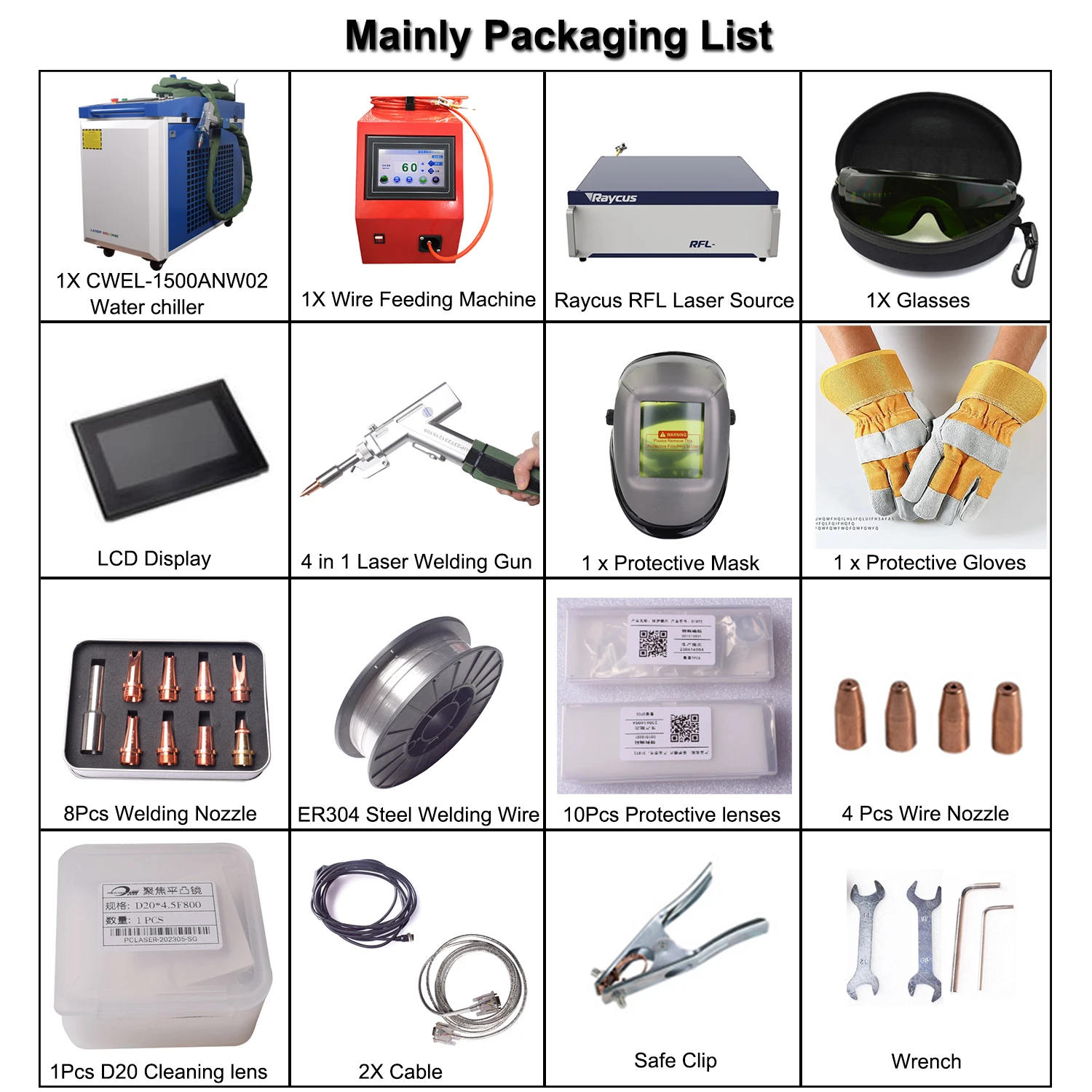

● s&Eine wassergekühlte Maschine

Die Wasserkühlung hat eine längere Arbeitszeit als Luftkühlung und kann den ganzen Tag arbeiten.

Schweißreinigungsmaschine

● mehr Materialien: Geeignet für Hochgeschwindigkeitsschweißen für verschiedene Materialien wie Stahl, Aluminium, Kupfer, Titan, Nickellegierungen, usw;

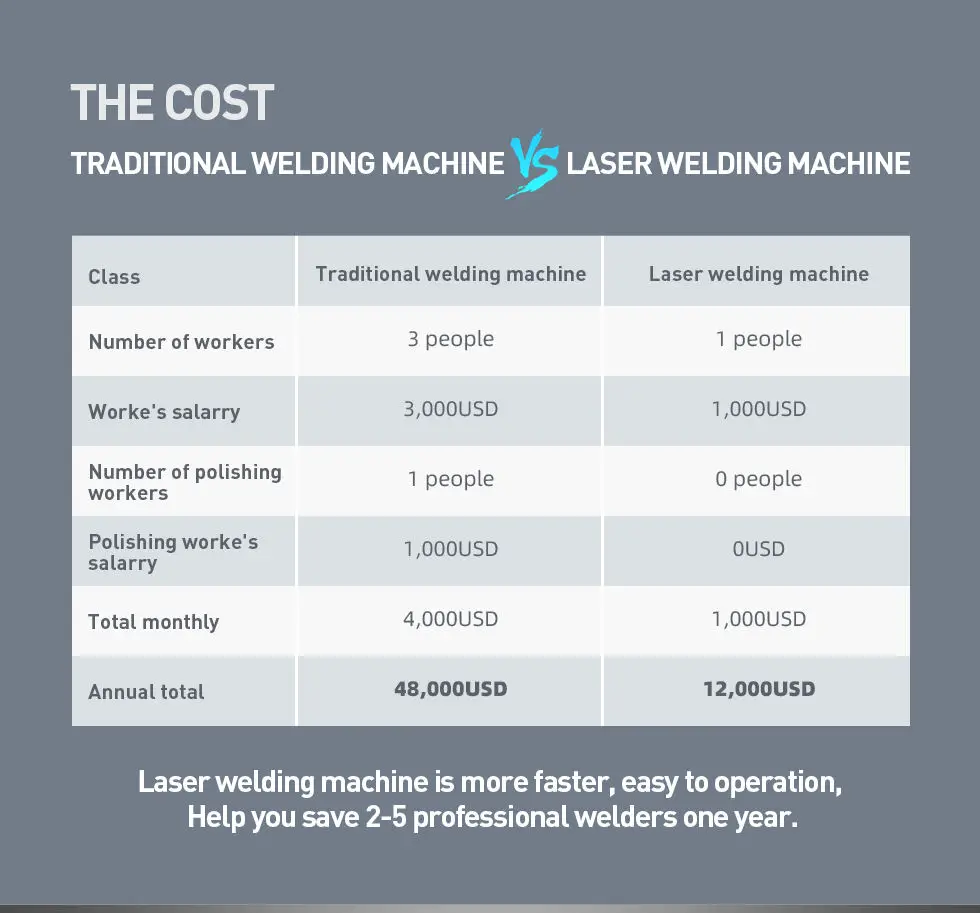

● schneller: 4 mal schneller als Tig und Mig

● Einfach: Vorbereitungsparameter kann die Lernkurve verkürzen, halbe Stunde -2 Std., Vom Anfänger zum Experten

● Eingang mit geringer Wärme: minimieren Sie die Teilverformung so weit wie möglich

Ur

4 In 1 Schweißerlaserlötautomaten Combo Laser Metall Reinigung Hauptmerkmale

1. Drei Arbeitsmodi, Schweißen + Schneiden + Reinigung. Einfacher Umschalten, Ich muss nur die Kupferdüse ersetzen,

Schalten Sie das System

2. Über Faserkabellänge

Standardlänge beträgt 10 m, Wenn Sie andere Bedürfnisse haben, Wir unterstützen die Verkürzung oder Verlängerung.

3. Hilfsgas: Stickstoff oder Argon

Wenn der Schweißoberflächeneffekt weiß und hell sein muss, Stickstoff oder Argon ist erforderlich

Wenn die Schweißoberfläche nicht erforderlich ist, Fügen Sie Druckluft -Gefrierentrockner hinzu, Luft ist in Ordnung.

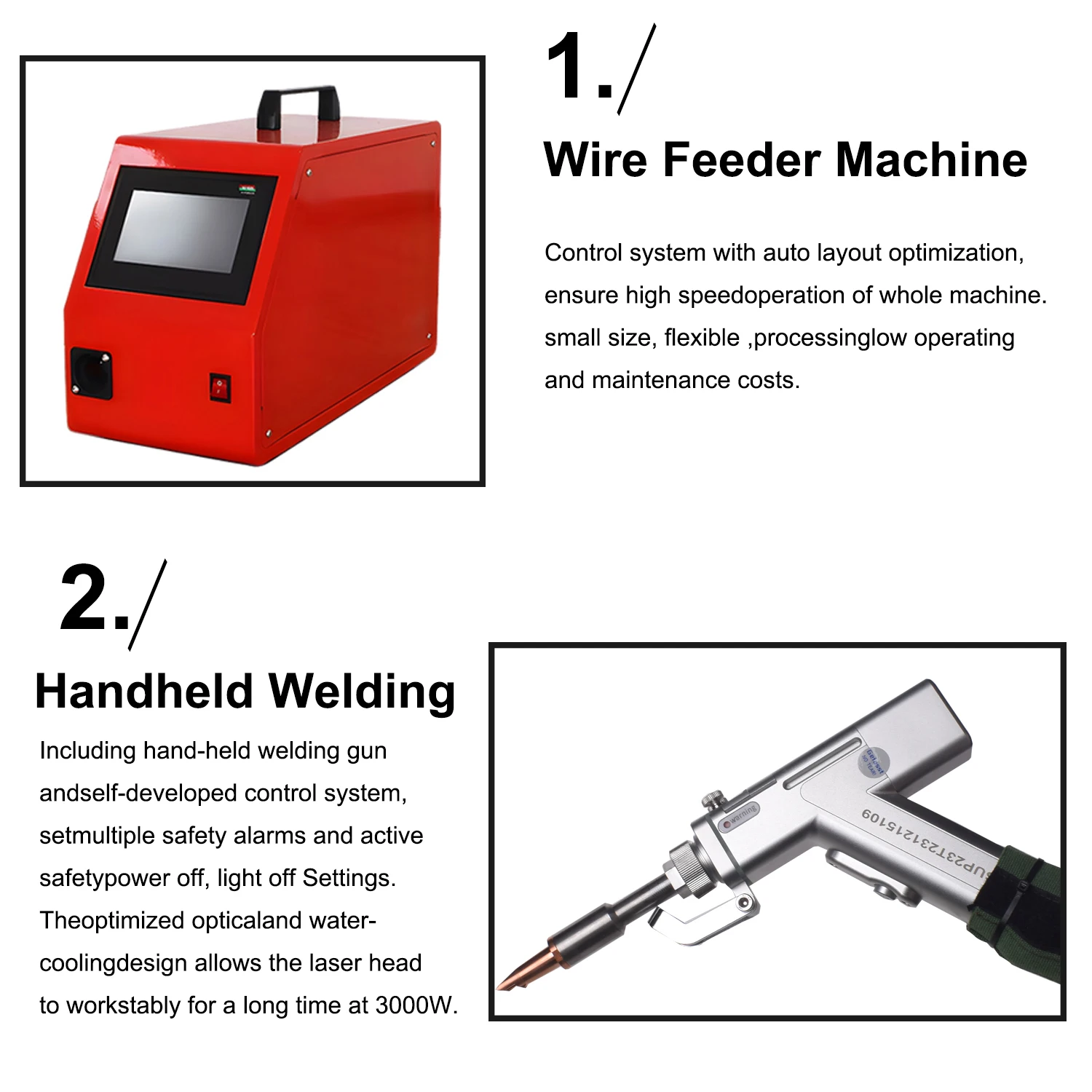

4. Über Drahtfutterautomaten

Es's Die Maschinenstandardkonfiguration, Wir werden Ihnen zusammen mit der gesamten Maschine an Sie senden.

5. Maschinengarantie: 3 Jahre für ganze Maschine, 2 Jahre für Lasergenerator.

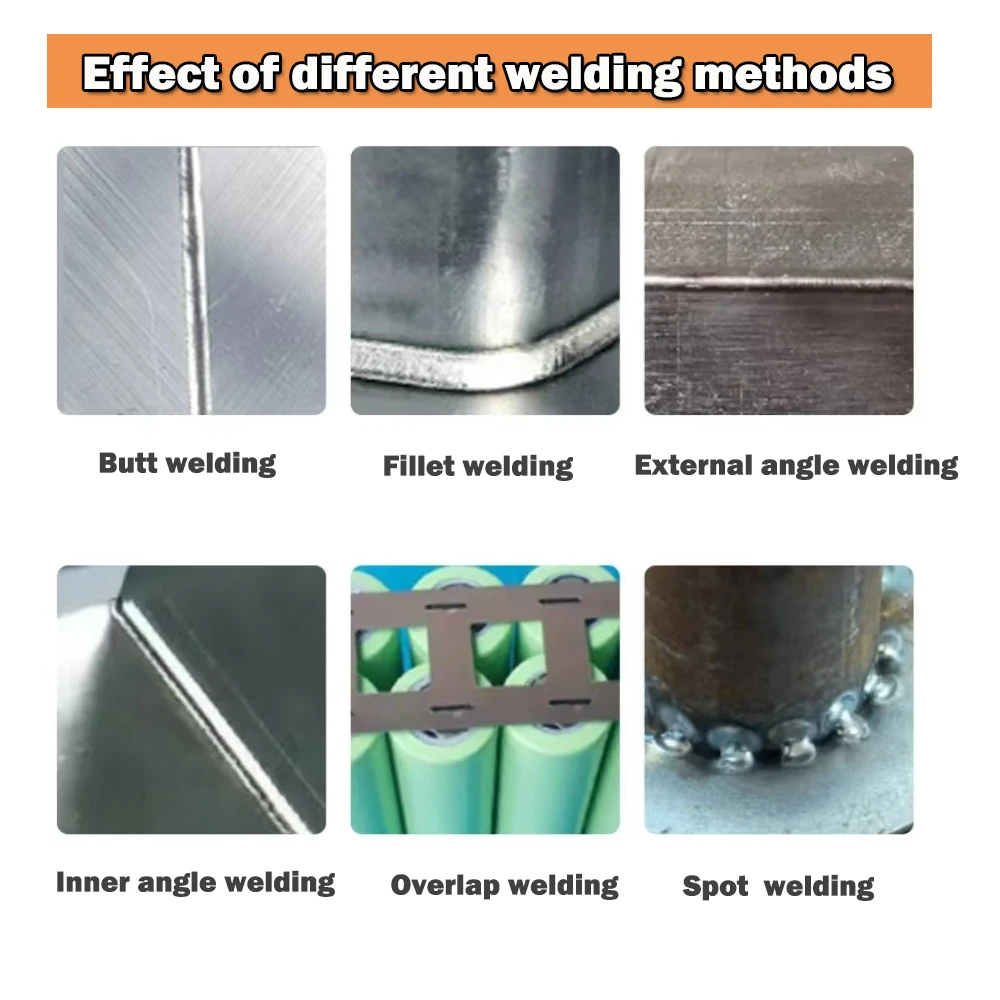

Laserschweißen

1) Die Schweißnaht ist glatt und schön,Das Schweißwerkstück hat keine Verformung, Das Schweißen ist fest, und nein

Der nachfolgende Schleifprozess ist erforderlich, Das spart Zeit und Kosten.

Schnelle Schweißgeschwindigkeit, 2~ 10 -mal schneller als herkömmliches Schweißen.

2) Einfacher Betrieb benötigt keine Schulung

Schweißnähte schön glatt und schön, Ich brauche keine Politur, Speichern Sie Ihre Zeit

Keine Verformung oder Schweißnarbe, festes Schweißen des Werkstücks.

3) Einfache Wartung

Das Laserschweißen hat weniger Verbrauchsmaterialien und eine lange Lebensdauer. Sicherer, umweltfreundlicher.

4) In Schrankküche und Badezimmer wild eingesetzt, Treppenaufzug, Regal, Ofen, Edelstahltür und Fenster

Leitplanke, Verteilungsbox, Edelstahlhaus.

Laserreinigung

1) Entfernung von Laserrost: Laserlicht kann leicht Rost entfernen, Nach dem Entfernen, Die Oberfläche wird in eine helle metallische Farbe oder Wiederherstellung der ursprünglichen Basisfarbe wiederhergestellt.

2) Entfernung von Laseröl: Öloberflächenölreinigung (kann gleichzeitig den Oxidfilm entfernen)

3) Entfernung von Laserfarben: Entfernt verschiedene Farben, einschließlich Auto Duco auf verschiedenen Substraten und Automobilen

4) Beschichtung abziehen (verzinkte Schicht, Aluminisierte Schicht, Schutzbeschichtung, usw.)

5) Entfernung der Aluminiumlegierung, Titanlegierung, Kupferlegieroxidfilm

6) Vorbehandlungen vor der Scheibe: Nach der Laserreinigung die Vorbehälter die Aluminiumlegierung, Die Schweißporositätsfehler werden effektiv unterdrückt

7) Reinigung nach dem Schweißen: Nichtkontakte NDT-Entfernung von Oxid- und Schlackenrückständen nach dem Schweigen

8) Pulste Laser mit Aluminiumlegierung entfernen vor dem Schweißen Schmutz- und Oxidfilm

Rezensionen

Es gibt noch keine Rezensionen.