Automatic glass bottles screen printers are made in a factory that specializes in tube screen printing machines. These machines are designed to automate the process of printing on glass bottles, increasing efficiency and accuracy. The factory likely produces a variety of screen printing machines specifically tailored for glass bottles and tubes. This technology has revolutionized the printing process for these products, allowing for faster production and higher quality results. By using these automatic screen printers, businesses can streamline their production process and increase output.

Automatic Glass Bottles Screen Printers Tubes Screen Printing Machine Factory

3 servo printing machine for cup and mugs (3 motors, left to right, up/down, controlled by spinning, PLC Control, Sensor)

Product description:

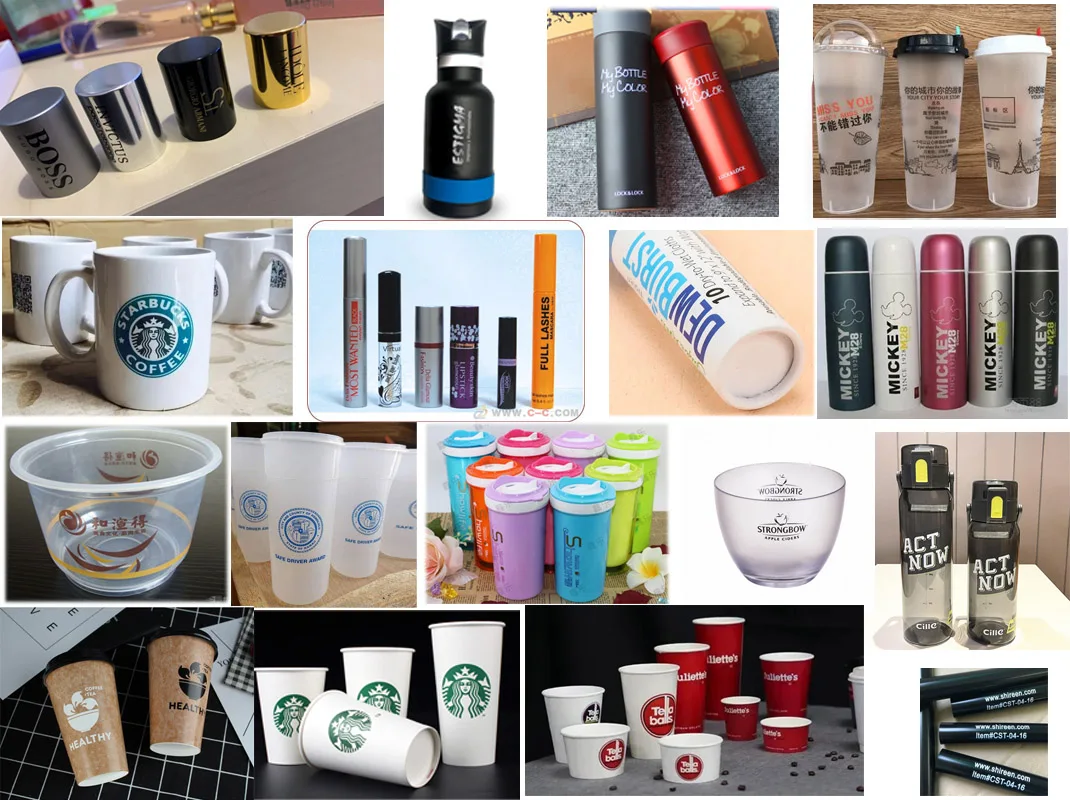

This model is a small high-profile curved screen printing machine, which is suitable to small cylinder printing, such as cosmetic bottles, hardware, stationery, etc. It has high printing precision, accurate positioning and fast speed. It can also be printed on circular substrate with a diameter of up to 120mm; the substrate material can be plastic, steel, ceramic, glass, etc.

Automatic Glass Bottles Screen Printers Tubes Screen Printing Machine Factory Features:

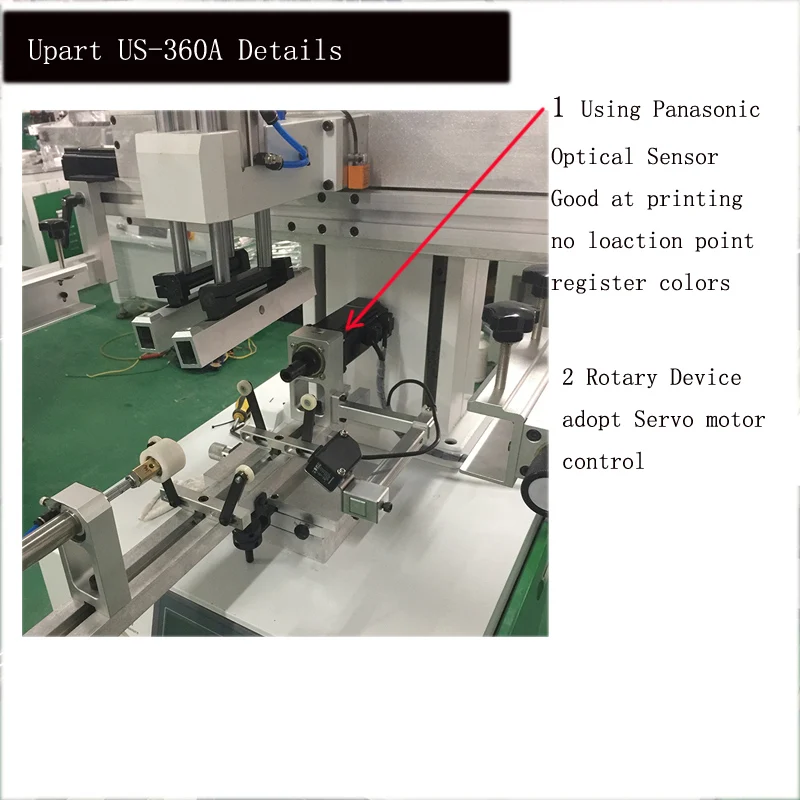

1. The screen printing machine adopts multi-servo to complete the automatic alignment color matching standard, and the color registration is accurate, and the color registration sensor is used for accurate alignment and color registration.

1. PLC microcomputer controls various function actions, with high degree of automation and simple and convenient operation.

2. Built-in four-digit automatic counter.

3, printing stroke and speed can be adjusted to meet different printing requirements.

4, the workbench can be fine-tuned up and down, left and right and plane swing angle, adjustment is convenient and fast.

5. Pneumatic print control with pressure adjustment system.

6, stable and reliable performance, bright and clear blue display, display the working status of the machine at any time.

7, high quality AUTONICS sensor and perfect fault alarm system.

8. Convenient foot switch, easy to operate and easy to maintain.

9. Light and strong alloy die-cast parts and wear-resistant imported bearing bushings.

10. Adopt international famous brand pneumatic components.

11. independent printing and ink return speed control.

Automatic Cylinder Screen Printers For Paper Cups with sensor for 2ed color register Parameters:

1. Maximum print diameter: less 120mm

2 The maximum print length: less 300mm

3 The fastest printing speed: 900pcs / hour

4 Power requirements: AC220V 50/60Hz

5 Rated power: 1600W

6 Air pressure requirements: 4 ~ 6bar

7 Machine Dimension: 1050mmx1100mmx1650mm/ Pack Dimension: 102X 90X 178cm=1.634CBM

8N.W/ G.W: 190 kg/ 236KGS

Remark:

1 Delivery Time: 20 days when get your payment;

2 Payment: 40% deposit in advance, the balance against the machine is ready.

3 Package: Plywood case

4 Warranty: 1 year

Servo Bottle Printing Machine With a Sensor Machine Parts:

Servo Bottle Printing Machine With a Sensor Actual picture for reference:

Reviews

There are no reviews yet.