Perché scegliere noi!!!

1. We have opened overseas after-sales service stations in many regions such as Europe and South America, support in the purchase of local door-to-door after-sales

2. We offer a three-year warranty. Lifetime online technical support. Our engineer provides one-to-one guidance

3. Vendite dirette in fabbrica, strictly control the quality at the same time can give you a preferential price

4. Support DDP home delivery service, we can take care of all the shipping work, you only need to receive at home. Molto comodo

5. The machine is easy to operate. Cleaning welding and cutting speed far exceeds the traditional mode, risparmiando tempo, effort and money

Penny

E-mail: [email protected]

WhatsApp: +86 133 6531 5506

Introduction to Products

Laser cleaning function

1. Non-contact cleaning, no damage to the material.

2. Adjustable cleaning width, adjustable focal length, easy to clean on large irregular workpieces, suitable for many industries.

3. Can be automated fast cleaning, cleaning efficiency is high.

4. High positioning accuracy and controllable cleaning thickness.

5. Just connect the power supply and you can use it, facile da usare

Laser welding function

1. It can weld 7.2 meters in one minute.

2. 10 times faster than traditional welding methods

3. three minutes to learn how to use

4. welding once forming, no need to polish welding gaps

5. Deep penetration, solid welding

6. Real-time monitoring, the machine is equipped with multiple alarms

7. Suitable for variety matals

Laser cutting fucntion

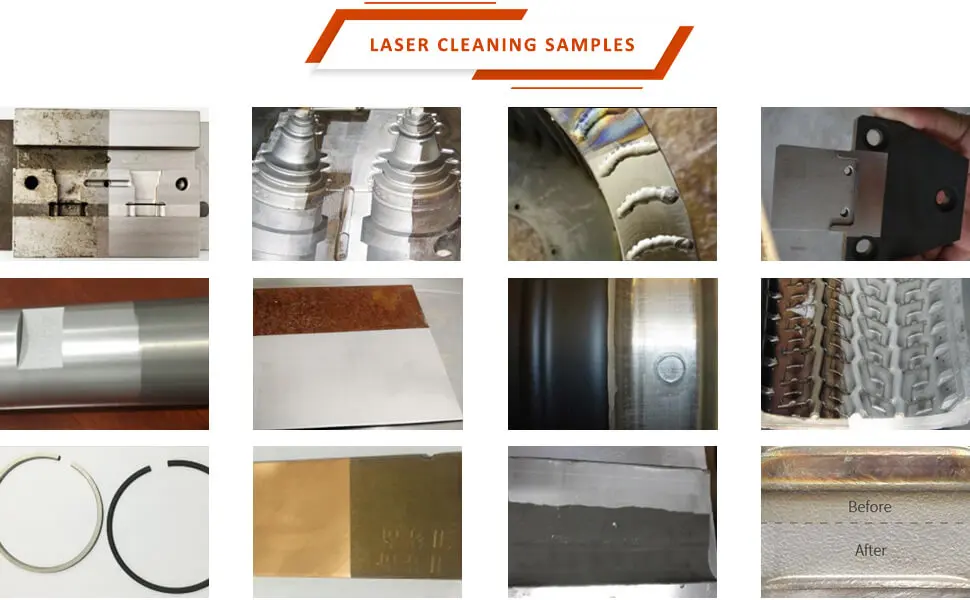

The fiber laser cleaning machinehas a good cleaning effect on iron, piastra in acciaio al carbonio, piastra in acciaio inossidabile, mold steel gear, aluminum plate, paint layer, e altri materiali. It can be used to clean the oxide layer, surface paint removal treatment, clean surface oil, macchie, e sporcizia, clean rubber mold residues, and meet the equipment cleaning requirements in the fields of the shipbuilding industry, parti auto, rubber molds, macchine utensili, and environmental protection industries.

Overall Display

Samples:

Below is the samples of our product. Maxcool fiber laser welding&pulizia&cutting machine suits for many materials, like Stainless steel, rame, alluminio, oro, chromium, argento, titanium, nickel and other metals or alloys

Feedback from Clients

La nostra azienda

(1) Pre-Sale Service

1) Professional sales team and engineer team provide professional technical Support

2) 24 hours of online service each day,you can contact us by email, WhatsApp, Skype, WeChat, Numero di telefono, e così via.

3) Test video and Sample support

4) OEM support

5) Certificate support: CE

(2) Services During The Sales

1) In the processing of production, our professional technical engineers inspect the processing to ensure the quality of products. After our machine finish, our engineer will make 24 hours test constantly and ensure the machine reach the best performance.

2) Shooting working video and machine pictures for customers' confirmation.Shoot delivery video, parts pictures in every detail, and save on file so that our after-sale team can help customers solve questions faster.

(3)After-Sale Service

1. 36 MESI GARANZA DI TUTTA MACCHINA(12 months for spindle

2.Three years warranty under normal operation and maintenance, if machine patrs are wrong, we provide same spare parts for free.

3. Out of 36 mesi, we will charge original for parts.4. Lifetime technical support and service free of charge.

(4)Technical Services:

1. Our staff can be sent to your company for installation and teaching if necessary.

2. Normally train by Phones/Whatsapp/Email.

3.Free teaching and operation will be provided at my factory.

Other Information:

Door to door service

Penny

E-mail: [email protected]

WhatsApp: +86 133 6531 5506

Recensioni

Ancora non ci sono recensioni.