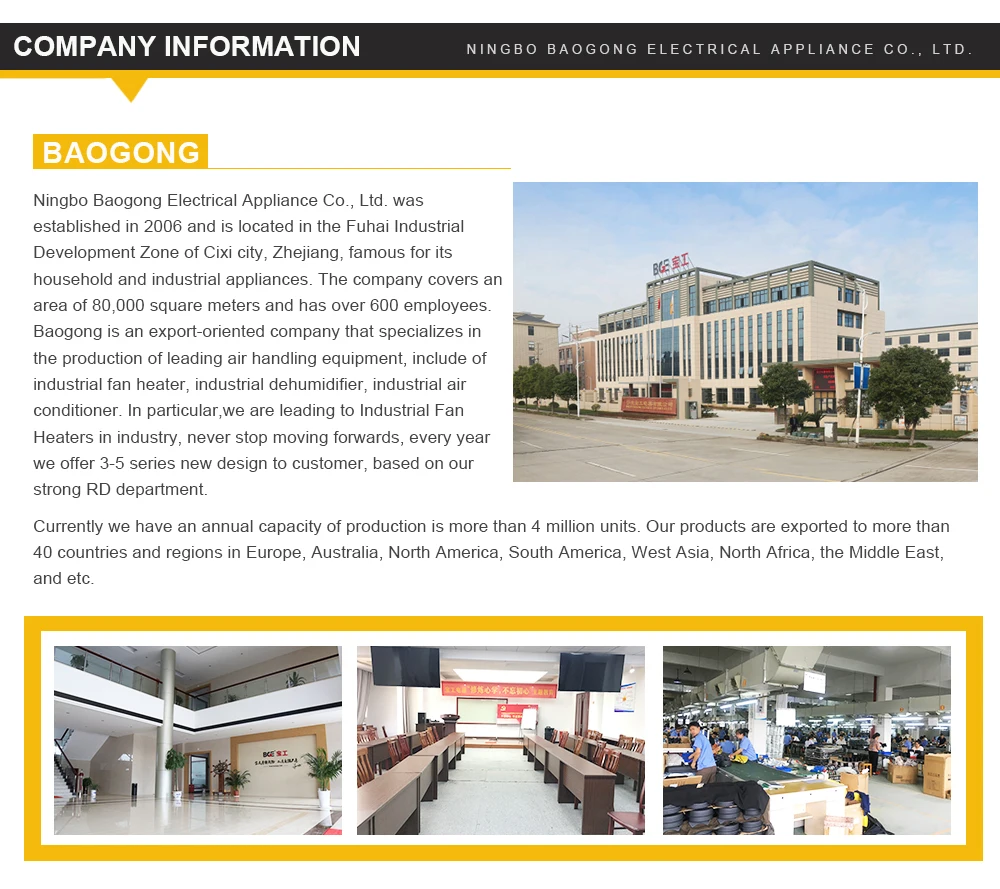

Presentación del calentador de ventiladores de gas industrial de la granja de invernadero de gama de 10kw BGE – La mejor solución para mantener su invernadero cálido y productivo durante todo el año.. Este calentador de propano portátil está diseñado específicamente para uso industrial, haciéndolo perfecto para operaciones agrícolas a gran escala.

Con una potente capacidad de calentamiento de 10kW, Este calentador de ventilador de gas puede calentar de manera rápida y eficiente su invernadero, Asegurar condiciones de crecimiento óptimas para sus plantas. El diseño portátil le permite mover fácilmente el calentador a diferentes áreas de su granja según sea necesario..

Además de sus capacidades de calentamiento, Este calentador de ventilador de gas industrial también está construido para durar. Fabricado con materiales de alta calidad., es duradero y confiable, dándole la tranquilidad de que resistirá los rigores del uso diario en su granja.

No dejes que el clima frío impida que tu invernadero prospere – Invierta en el calentador de ventiladores de gas industrial de 10KW BGE Greenhouse Farm y disfrute de una temporada de crecimiento productiva y exitosa. Ordene el suyo hoy y vea la diferencia que puede hacer para su granja.

|

Modelo no

|

BGA-10

|

BGA-15-13

|

BGA-30-13

|

BGA-50-13

|

|

Fuerza (W.)

|

10 000

|

15 000

|

30 000

|

50 000

|

|

Suministro eléctrico

|

220-240V ~ 50 Hz

|

220-240V ~ 50 Hz

|

220-240V ~ 50 Hz

|

220-240V ~ 50 Hz

|

|

Saliente de aire (m3/h)

|

320

|

320

|

650

|

872

|

|

Consumo de combustible (kg/h)

|

0.73

|

1.09

|

2.18

|

3.63

|

|

Presión (mbar)

|

300

|

300

|

700

|

1500

|

|

Espacio de calefacción (metro 2)

|

150

|

225

|

450

|

750

|

|

Potencia del motor (W.)

|

25

|

25

|

80

|

80

|

|

Clase IP

|

No

|

No

|

No

|

No

|

|

Tipo de gas

|

G30

|

G30

|

G30

|

G30

|

|

Temperatura del entorno usado

|

-15~ 30

|

-15~ 30

|

-15~ 30

|

-15~ 30

|

10KW BGE Greenhouse Farm Industrial Gas ventilador de gases de gases Propano portátil Calentadores de espacio de aire forzado en venta

2. Función en gas propano (GLPG)

3. Con protección de sobrecalentamiento

4. Boquilla especial, con un suministro de oxígeno fuerte, haga la combustión por completo

5. Protección de corte Avenio de gas Fugas

6. Diseño de operación de deflación y encendido

7. Ideal para sitios de construcción, edificios de servicios públicos/granjas, eventos deportivos, graneros y fábricas

8. Clase impermeable IPX4

9. Operación completamente automática controlada por PCB con estadísticas de temperatura ambiente

10. Regulador & 1.5M manguera incluida

*IQC (Control de calidad entrante): Todos los materiales y componentes entrantes

*IPQC (En control de calidad de proceso): Pantalla de seda; Estampado de metal; Soldadura; Revestimiento; Subconjunto; Ensamblaje final

*LQC (Estación de control de calidad en línea): 100% Funcionalidad y pruebas de seguridad; 100% Verificación visual de la estética

*Chabolla (Control de calidad final): Inspecciones previas al envío

*OQC (Control de calidad superior): Inspecciones aleatorias; Prueba de vida

4.Nuestro propio departamento de diseño. Precisamente hacerse obras de arte.

5.Reclamos / CAPA (Acción correctiva y preventiva) servicio proporcionado.

Haga un seguimiento de su pedido,retroalimentación rápidamente .

servicio para servirle de todo corazón.

Reseñas

Aún no hay reseñas.